Old Bailey

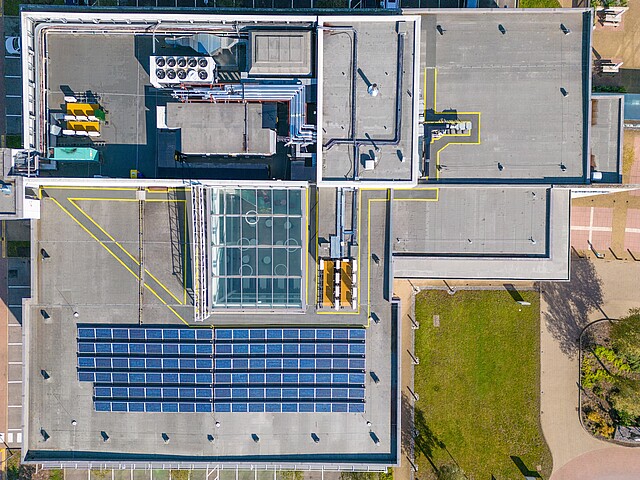

Transformation of terrace areas across three floors of an occupied building

Project: Old Bailey

Size: 800 sq m

Substrate: Concrete

WestWood products:

- Wecryl 230 waterproofng

- Weplus SA VB

- Weplus prelaminated tissue-faced PIR & 12mm cement particle board

- Wecryl 333

- Wecryl 488

- Weplus pedestals & porcelain tiles

- Wecryl 815 Fibre Putty

The Challenge

The existing terraces of this impressive office building had been designed using an inverted roof system on a zero-fall structural deck. Defects in the original design and sequential works had caused the system to fail resulting in water ingress to the floors below.

The Solution

WestWood’s Wecryl 230 was selected as the new waterproofing system for terraces on levels 8, 9 and 20. As there is no need for a mechanical termination, complex and awkward detailing, including low upstand heights were also effectively waterproofed.

Pre-laminated insulation, cement boards and a carrier membrane were installed before the upstands were waterproofed for a second time. Wecryl 230 Thix was applied and taken as high as possible underneath the perimeter detailing and the windowsills within the building.

Once the waterproofing membrane had been applied, the Wecryl 333 self-levelling mortar with quartz sand broadcast, and Wecryl 488 sealer coat were added.

The fixing plates to the balustrades required careful consideration on how best to be waterproofed. The insulation was finished short around these areas to allow a pitch pocket detail to be created, which was then infilled with Wecryl 333. The remainder of the insulation and carrier membrane were then applied before Wecryl 815 Fibre Putty and Wecryl 230 Thix were used to create a robust watertight detail around the plates.

The Outcome

WestWood’s Wecryl 230 waterproofing system provided a robust, self-terminating membrane which is tested and accredited to perform underneath standing water at zero falls.

The Wecryl 333 self-levelling mortar with quartz sand broadcast and Wecryl 488 sealer coat created a homogenous membrane, providing waterproofing and a robust protective layer before the pedestals and porcelain tiles were added.

In recognition of its success and complexity, the project was highly commended in the ‘Liquid Roofing Project of the Year in a Buried Application’ category at the LRWA awards.